Our production department is equipped with a diverse range of advanced machinery, including CNC turning and milling centers, as well as laser and water jet cutting machines, enabling us to manufacture high-precision components across various industries. Our CNC turning and milling machines offer exceptional accuracy and repeatability, ensuring that each part meets exact specifications. The laser and water jet machines provide versatility in material cutting, allowing us to handle complex geometries and a wide array of materials with precision and efficiency. Quality control is integral to our production process; every part we produce undergoes rigorous inspection and testing to ensure it meets the highest standards of quality and performance. By maintaining strict quality control protocols, we guarantee that our clients receive reliable, high-quality components that meet their specific needs and expectations.

.

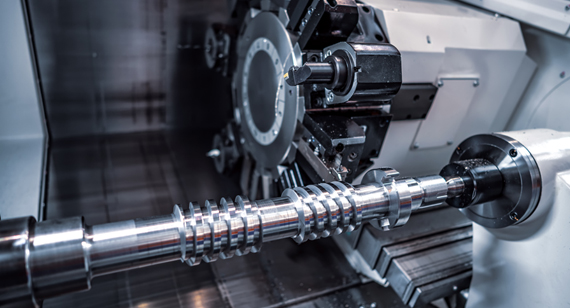

CNC Turning Machines

Our CNC turning machines are at the forefront of precision engineering, offering exceptional capabilities for both series production and individual component fabrication. These state-of-the-art machines are equipped with advanced control systems that allow for high-speed, accurate machining, ensuring each piece is manufactured to exact specifications. Whether producing large batches or custom single parts, our CNC turning machines maintain consistent quality and precision across all projects. This versatility enables us to efficiently handle a wide range of materials and complex geometries, making us a reliable partner for clients seeking precision and reliability in their manufacturing processes. Our commitment to excellence in CNC turning ensures that each component not only meets but exceeds industry standards for quality and performance.

CNC Milling Machines

Our CNC milling machines represent the pinnacle of precision and versatility in modern manufacturing. Equipped with cutting-edge technology, these machines offer unparalleled accuracy and efficiency in producing complex components. They are capable of executing intricate designs and shapes across a wide range of materials, from metals to composites. With the ability to perform multi-axis machining, our CNC milling machines ensure that each part is crafted with exacting precision and consistent quality. Whether producing high-volume runs or custom, one-off pieces, our CNC milling capabilities enable us to meet the diverse needs of our clients with exceptional reliability and speed. Our dedication to precision and innovation ensures that every component meets stringent quality standards, delivering superior performance and durability.

CNC Laser Machine

Our 2D laser cutting capacity is very advanced because of our load—unload system which runs lights out and can make quick turnaround times for our customers. The cutting in two dimensions is a domain of a CO2 laser. Basically, the cutting of metals with lasers happens through the local heating of the material above its melting point in the focal point of the focused laser. The resulting molten material is ejected by a gas flow oriented coaxially to the laser beam so that a kerf is formed.

.

CNC Waterjet Machine

We offer professional and flexible Waterjet cutting services to all our customers from project designing to completion. At Optitech, We provide precision and intricate plate Waterjet cutting for a wide variety of extremely dense and thick materials. Using our latest technology, a waterjet CNC cutting machine from (KMT Water jet Systems, Germany), is one of the most powerful waterjet cutting machines.

.

.

Quality Control

Quality control is of paramount importance in our company, especially when it comes to CNC machine production. Our commitment to precision and excellence is reflected in the rigorous quality control measures we implement throughout the manufacturing process. Each component produced by our CNC machines undergoes meticulous inspection to ensure it meets the highest standards of accuracy and reliability. Utilizing state-of-the-art measurement technologies and detailed testing protocols, our quality control team verifies that every part adheres to exact specifications and tolerances. This stringent approach not only prevents defects but also ensures consistency across production batches, reinforcing our reputation for delivering high-quality, dependable products. By prioritizing quality control in our CNC machining operations, we guarantee that our clients receive components that fulfill their exact requirements, enhancing both customer satisfaction and the long-term performance of their products.

Engineering Production Group Modeling, Analysis and production

Engineering Production Group Modeling, Analysis and production